Machine Vision is a branch of computer science that has really grown over the last 20

1950’s – Two dimensional imaging for statistical pattern recognition developed: Gibson introduces optical flow and based on his theory mathematical models for optical flow computation on a pixel-by-pixel basis are developed.

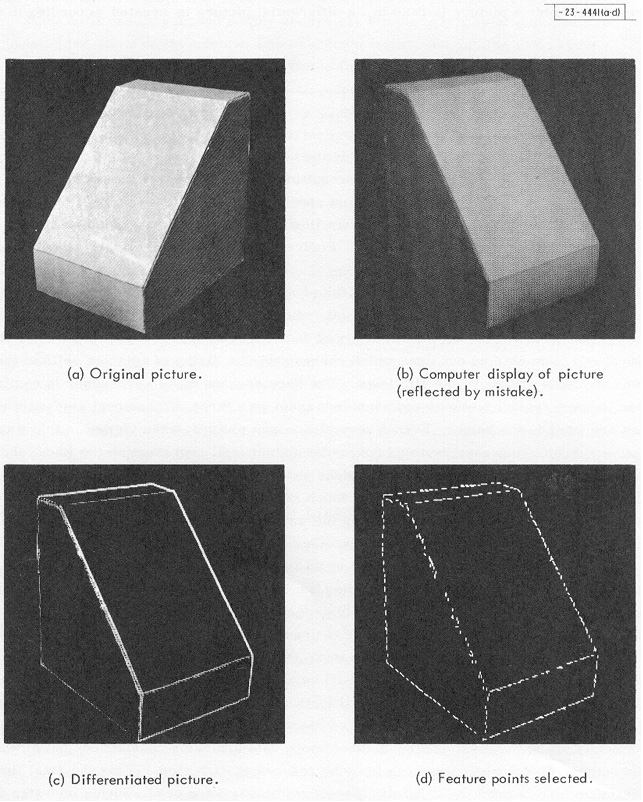

1970’s – MIT’s Artificial Intelligence Lab opens a “Machine Vision” course – Researchers begin tackling “real world” objects and “low-level” vision tasks (i.e. edge detection and segmentation: In 1978 a breakthrough was made by David Marr (at the MIT AI lab) who created a bottom up approach to scene understanding through computer vision. This approach starts with a 2D sketch which is built upon by the computer to get a final 3D image.

1980’s – Machine vision starts to take off in the world of research, with new theories and concepts emerging: Optical character recognition (OCR) systems were initially used in various industrial applications to read and verify letters, symbols, and numbers. Smart camera’s were developed in the late 80’s, leading to more wide spread use and more applications.

1990’s – Machine vision starts becoming more common in manufacturing environments leading to creation of machine vision industry: over 100 companies begin selling machine vision systems. LED lights for the machine vision industry are developed, and advances are made in sensor function and control architecture, furthering advancing the abilities of machine vision systems. Costs of machine vision systems begin dropping.

MACHINE VISION TODAY

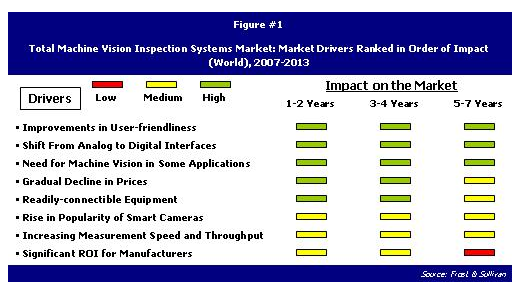

Today machine vision systems continue to move forward. 3D vision systems that scan products running at high speeds are becoming affordable, and systems that do everything from thermal imaging to slope measurement can be readily found. Machine vision continues to ba growing market, with many new advances driven by the wide array of possible applications and the other market drivers in Figure #1, from an article by Frost Sullivan.

Many challenges still exist in the development of machine vision systems. The commonly accepted “bottom-up” framework developed by Marr is being challenged, as it has limitations in speed, accuracy, and resolution. Many modern machine vision researchers advocate a more “top-down” and heterogeneous approach, due the difficulties Marr’s framework exhibits. A new theory, called “Purposive Vision” is exploring the idea that you do not need complete 3D object models in order to achieve many machine vision goals. Purposive vision calls for algorithms that are goal driven and could be qualitative in nature.

Another area where machine vision is advancing in conjunction with EEG sensors in Gesture Based Interfaces. Gesture based interfaces allow operators to control computers and machinery with thoughts and gestures rather than with keyboards and other input devices. Check out EPIC’s other blog post about the implications of Gesture Based interfaces on manufacturing, and this video on gesture based interfaces being used in combination with brain-wave sensors.

EPIC Systems, Inc. is a full service machine vision solution provider and line integrator. We can integrate and automate your factory with a more traditional PLC touchscreen control system, or install some of the gesture-based technologies entering the market place. We provide a wide variety of machine vision applications that can be found on our machine vision site. For more information on EPIC’s machine vision abilities, please contact an EPIC engineer today.